Bringing contractors on-site can expose your business to serious safety risks, especially if there’s no system in place to manage them.

Unlike your core team, contractors often have different backgrounds, varying experience levels, and limited knowledge of your safety policies or company regulations.

That makes a strong contractor safety management program essential.

A well-designed program helps make sure that every contractor, regardless of role or location, meets your health and safety requirements, understands your safety expectations, and follows the right protocols from day one.

Without it, you face increased exposure to potential hazards, OSHA citations, and breakdowns in accountability.

If you need help with implementing one, we’ll cover everything you need to know in this guide.

What Is Contractor Safety Management?

Contractor safety management refers to the systems and procedures a company uses to make sure that all contractors, such as temporary workers, subcontractors, and third-party service providers, comply with workplace safety requirements.

It’s about more than assigning tasks or signing contracts. It involves managing risks, enforcing safety standards, and making sure all contractors understand the health and safety expectations of the job site.

Why Contractor Safety Management Matters

Contractors play a critical role in the workforce. But when you bring in outside teams, you’re also introducing new variables: different work habits, unfamiliarity with site-specific safety protocols, and inconsistent knowledge of your safety standards.

That’s why managing contractor safety is a priority, not an option. Without an effective contractor safety management system in place, your organization faces serious consequences, such as:

Increased safety risks

Untrained or poorly supervised contractors can create potential dangers for themselves and others, especially in high-risk settings like construction, manufacturing, or energy.

Regulatory exposure

Failing to comply with Occupational Safety and Health Administration (OSHA) requirements, contract terms, or government regulations can lead to costly fines, failed inspections, or legal penalties.

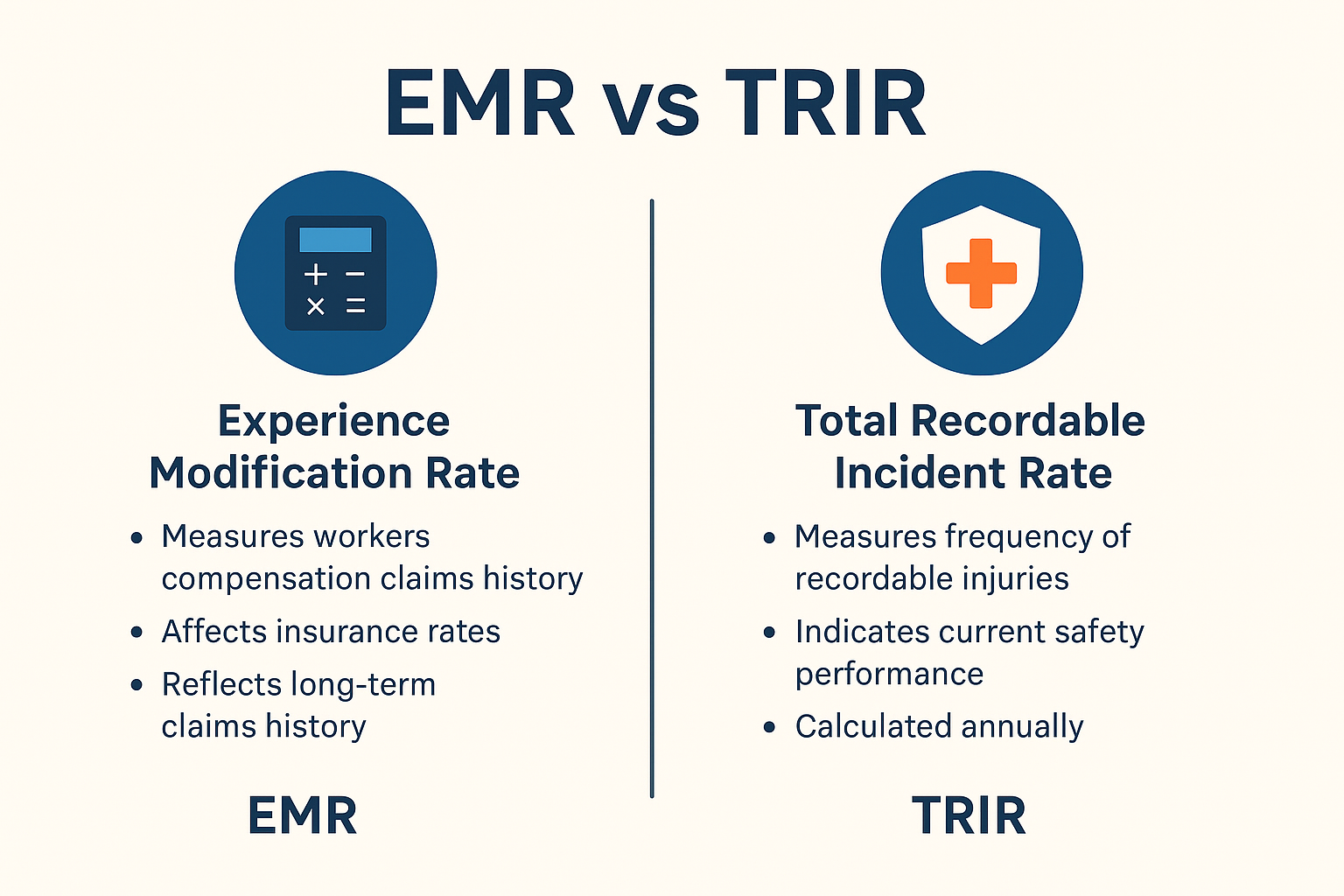

Damaged safety performance

One incident involving a contractor can impact your entire organization’s safety record, insurance rates, and public reputation.

Missed compliance gaps

Without structured processes, it’s easy to overlook critical checks like verifying safety equipment, ensuring proper use, or confirming adequate training.

What You Gain with Contractor Safety Management

A strong contractor safety program helps you:

- Make sure every contractor receives necessary training and follows job site procedures

- Align outside workers with your company regulations and safety rules

- Reduce incident rates, protect your workforce, and meet regulatory requirements

Whether you’re hiring contractors for a short-term project or managing an entire supply chain, the risks are real, and the solution is a clearly defined, consistently enforced contractor safety management program.

Key Elements of an Effective Contractor Safety Program

To protect your workforce, meet regulatory requirements, and avoid unnecessary risk, you need more than policies. You need a structured, repeatable system.

An effective contractor safety program includes specific checkpoints that cover the full contractor lifecycle, from selection to post-job evaluation.

Here are the key components to put in place:

Prequalification and Risk Assessment

Before bringing anyone on-site, determine the required qualifications for the role.

Screen contractors for safety performance, review their incident history, and assess whether they meet both legal and occupational health standards.

You should also use a structured risk assessment to identify potential hazards tied to the scope of work.

Contractor Onboarding and Orientation

Every contractor should receive clear information on safety rules, company regulations, job site hazards, and their role in maintaining a safe work environment.

Orientation should cover emergency procedures, reporting systems, and machine guarding, along with any specific health and safety expectations.

Safety Training and Certification Verification

Contractors must receive and complete all relevant training before starting work, whether that’s fall protection, equipment safety, or other industry-specific tools.

Always provide adequate training and verify documentation through a training record management system.

Work Permits and Access Control

Implement a formal work permit process to manage access to restricted areas and high-risk tasks.

This makes sure only authorized personnel are operating in sensitive or hazardous zones.

On-Site Oversight and Supervision

Assign clear accountability for monitoring contractor performance during the project.

Supervisors should also regularly monitor for compliance, safe practices, and any emerging safety concerns.

Incident Management and Feedback

If an incident occurs, it must be logged, investigated, and followed by corrective actions.

Build in procedures to report incidents quickly, provide feedback to employers, and identify contributing factors for further analysis.

Post-Job Review and Documentation

Once the job is complete, evaluate the contractor’s overall safety performance, compliance with contract terms, and any areas for improvement.

Keep records to inform future decisions and demonstrate due diligence to regulatory bodies.

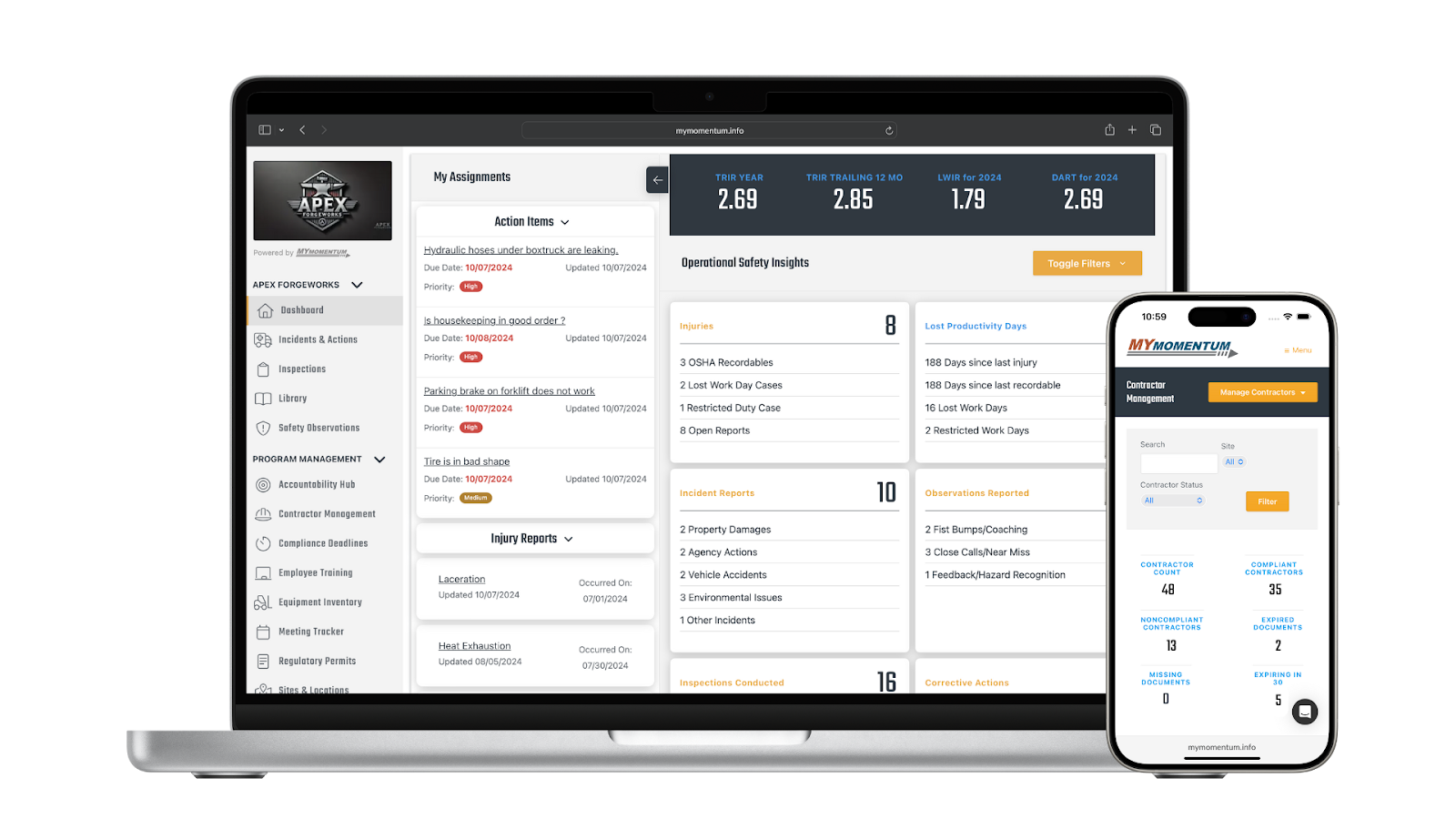

Why MyMomentum Works for Contractor Safety

With MyMomentum, you can:

- Track required contractor qualifications, safety training, and certifications in one place

- Digitize orientations and enforce site-specific safety expectations and protocols

- Use integrated tools for issuing and tracking work permits, incidents, and corrective actions

- Create auditable records to satisfy regulatory requirements and OSHA compliance

- Provide a unified experience across multiple sites with real-time updates and mobile access

Whether you’re hiring for a single project or managing contractors across your entire supply chain, MyMomentum gives you the visibility, tools, and structure to reduce risk, stay compliant, and build a stronger, safer workforce.

Want to see how it fits your operations? Schedule a demo to see how EHS Momentum and MyMomentum can help you strengthen your contractor safety program from the ground up.

Mistakes to Avoid in Contractor Safety Management

Even well-intentioned organizations can fall short when managing contractors. Without a standardized approach, critical gaps can appear, which can lead to compliance issues, safety risks, and preventable incidents.

Here are some of the most frequent mistakes that undermine an otherwise strong contractor safety management program:

Assuming Contractors Follow Internal Policies

Never assume that contractors are familiar with your safety protocols or safety policies. Unlike employees, they may not have been exposed to your workplace safety culture or expectations.

Always provide clear orientation and enforce the same standards you apply to your core workforce.

Failing to Verify Training or Qualifications

A common oversight is skipping the review of required qualifications or assuming credentials are current.

Without confirming relevant training, contractors may be operating machinery or working in hazardous areas without the necessary training or certifications.

Inconsistent Documentation and Recordkeeping

In many organizations, contractor records are fragmented or stored separately from internal safety management systems. This makes it hard to prove compliance or evaluate performance.

Use a centralized reporting system or software solution to track qualifications, incident reports, and evaluations.

Lack of Active Oversight on the Job Site

Contractors are sometimes left unsupervised once the work begins.

Failing to regularly monitor activities increases the risk of unsafe behavior, especially when safety equipment or proper use protocols are ignored.

Ignoring Incidents Involving Contractors

When a contractor is involved in a safety incident, it’s sometimes treated with less urgency than if a full-time employee were involved. This leads to missed corrective actions, poor incident management, and gaps in root cause tracking.

Every incident, regardless of who is involved, must be documented and reviewed.

No System for Performance Feedback

Contractors should be held to performance metrics, just like internal teams.

Failing to provide feedback to employers or track contractor performance can result in repeat safety violations or missed learning opportunities.

Simplify Contractor Safety Management with EHS Momentum

As more companies rely on subcontractors and third-party labor, maintaining consistent safety standards, documentation, and oversight becomes harder to manage without the right support.

EHS Momentum helps companies implement clear, accountable, and scalable contractor safety management programs.

With years of industry experience, we understand the real-world challenges of managing contractor safety, from prequalification and safety training to incident management, documentation, and post-job performance reviews.

At the center of our approach is MyMomentum, a cloud-based platform designed to give you full control over contractor onboarding, compliance tracking, and field-level performance monitoring.

FAQs About Contractor Safety Management

Is a contractor safety program required by OSHA?

While OSHA doesn’t mandate a specific contractor safety program, it holds employers responsible for maintaining a safe work site, even when using contractors.

You must determine required qualifications, deliver adequate training, and conduct regular safety inspections to meet legal requirements and protect worker safety.

What is contractor risk management?

Contractor risk management involves identifying and controlling potential risks tied to contractors working on your site.

This includes verifying required qualifications, enforcing health and safety policies, and using a software solution to monitor performance, track training, and manage hazards proactively.

What is a Safety Management System in construction?

A Safety Management System (SMS) in construction is a structured approach to managing worker safety, achieving compliance, and reducing incidents.

It includes safety audits, safety inspections, training protocols, and policies that hold both employees and contractors accountable.

What is a contractor safety plan?

A contractor safety plan outlines the rules, expectations, and procedures for safely managing contractors on a job site.

It makes sure that contractor management aligns with company policies, helps provide feedback to employers, and defines when additional training or oversight is needed for an effective program that improves safety and can increase productivity.