Managing hazardous operations comes with high stakes. When lives, property, and production are on the line, reactive safety isn’t enough. You need systems in place that anticipate problems before they escalate.

That’s the purpose of process safety management (PSM), a framework designed to reduce the risk of catastrophic chemical releases and ensure the safe handling of highly hazardous substances.

However, keeping up with all the moving parts, like risk assessments, operating procedures, training, and incident investigations, can quickly overwhelm any team.

That’s where process safety management software becomes essential. With the right platform, you can centralize documentation, streamline workflows, ensure compliance with OSHA’s PSM standards, and strengthen overall safety performance.

Here are five of the best options.

What Is Process Safety Management Software?

Process safety management software is a digital solution designed to help organizations implement and maintain a structured PSM program.

It streamlines the documentation, tracking, and execution of processes required under the Occupational Safety and Health Administration’s (OSHA) Process Safety Management standard (29 CFR 1910.119), especially for industries that handle highly hazardous chemicals.

This type of software brings together key components of process safety, such as process hazard analysis, incident investigation, training, and mechanical integrity, into one integrated platform.

It provides tools for assigning tasks, conducting audits, managing procedures, and maintaining records, all while enabling real-time visibility into operational risks and compliance status.

The goal? To identify potential hazards, mitigate risk, and ensure that safety-critical processes are consistently followed across your entire organization.

Why Process Safety Management Matters

When you’re dealing with hazardous materials or complex operations, a small oversight can have catastrophic consequences.

That’s why process safety management is essential, not just for compliance, but for protecting people, property, and the environment.

Reduces the Risk of Major Incidents

PSM is designed to identify potential hazards before they lead to explosions, chemical releases, or other high-impact events.

A structured PSM program helps you manage operational risks systematically, rather than reactively.

Achieves Regulatory Compliance

Industries that handle highly hazardous chemicals must comply with OSHA’s PSM standard.

Using process safety management software helps organizations maintain compliance by automating documentation, deadlines, and required procedures.

Improves Operational Discipline

From equipment maintenance to training and emergency planning, PSM enforces consistent safety practices across all levels of the business.

It makes sure tasks are not only completed, but completed correctly.

Supports Continuous Improvement

With access to real-time data, incident reports, and audit results, companies can spot trends, implement corrective actions, and continuously improve their PSM program.

It’s a proactive strategy to elevate safety and performance over time.

Process Safety Management Software: Top 5 Options

Whether you’re building a PSM program from scratch or tightening up an existing one, the right software platform can make or break your ability to stay compliant, reduce incidents, and improve accountability across teams.

Here are five trusted platforms built for the job.

1. MyMomentum (by EHS Momentum)

MyMomentum is a mobile-first safety management platform designed for small to mid-sized companies that need robust OSHA compliance tools without the complexity or cost of enterprise software.

Built around three principles — useful, simple, and affordable — to help teams digitize inspections, manage incidents, track training, and monitor corrective actions across high-risk operations.

All Your Process Safety Information, in One Place

With MyMomentum, you can manage and store:

- OSHA-mandated documentation (SDSs, logs, permits)

- Safety programs and policies

- Site and equipment inspection records

- Corrective action logs and maintenance issues

- Training records and deadlines

- Job hazard assessments and BBS observations

All documents are version-controlled, accessible remotely, and automatically backed up.

Real-Time Hazard and Incident Reporting

MyMomentum allows employees to submit incidents, unsafe conditions, or permit issues directly from the field via mobile device, with photo attachments, notes, and alerts to supervisors.

This real-time feedback system helps track open issues and overdue tasks, monitor recurring problems across facilities, and build a digital audit trail for OSHA compliance.

Automated Compliance Monitoring

The platform supports key areas of OSHA’s PSM standard by:

- Tracking training and recertification deadlines

- Logging safety committee meetings

- Notifying managers of items due or overdue

- Managing regulatory permits

- Generating OSHA 300/301 logs

Mobile-Ready and Easy to Adopt

The mobile-first interface is intuitive and designed to work in industrial settings, not just offices. QR code-enabled inspections, automatic weekly admin reports, and mobile alerts improve engagement and accountability across your workforce.

Want to improve documentation, reduce manual overhead, and foster a stronger safety culture without an enterprise price tag? Book a demo of MyMomentum now.

2. VelocityEHS

Source: EHS.com

VelocityEHS offers an integrated Environmental, Health, and Safety (EHS) platform with specialized tools for process safety management. It’s geared toward mid-to-large organizations that manage hazardous materials and high-risk operations.

Key Process Safety Management Features

- Tracks process safety information, including chemical data, operating procedures, and equipment specs

- Supports comprehensive risk assessments and process hazard analyses (PHAs)

- Facilitates incident investigations with root cause analysis and corrective action tracking

- Integrates with broader EHS workflows (training, audits, inspections, compliance deadlines)

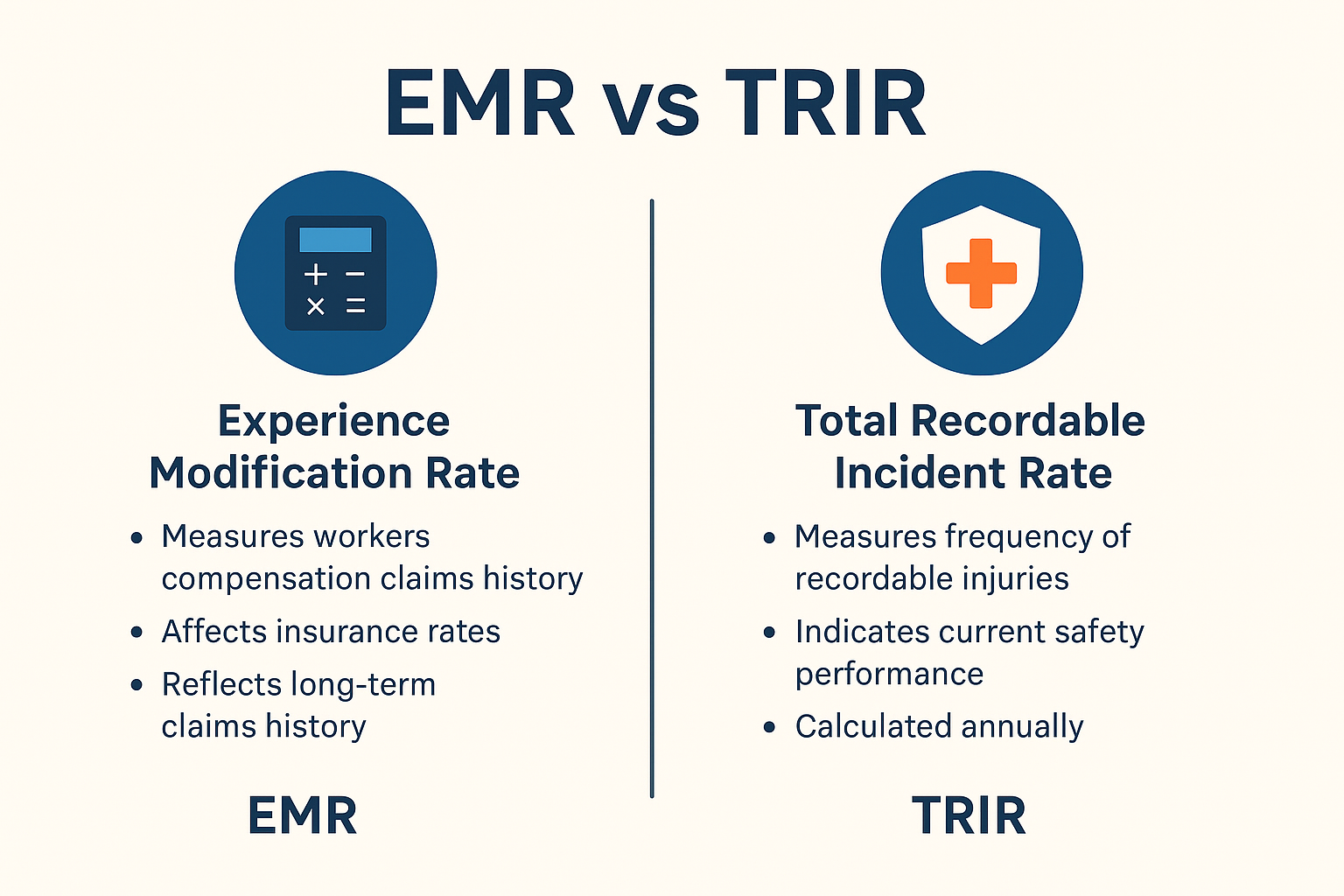

- Dashboards for tracking metrics like TRIR, EMR, overdue corrective actions, and audit findings

- Supports audit scheduling, documentation, and regulatory inspection readiness

- Enables emergency planning documentation and testing

Pros

- Comprehensive PSM coverage with strong data management tools

- Intuitive dashboards and visualizations for real-time decision-making

- Seamlessly integrates with other VelocityEHS modules (training, inspections, etc.)

- Strong support and industry reputation

Cons

- More expensive than smaller or single-focus tools

- Initial setup and configuration can be time-consuming

- Some users report a steep learning curve when deploying across multiple sites

3. SpheraCloud

Source: Sphera.com

SpheraCloud offers a robust, enterprise-level solution for organizations seeking deep control over operational risks and compliance across complex processes.

It’s especially well-suited for industries handling highly hazardous chemicals and requiring end-to-end process safety workflows.

Key Process Safety Management Features

- Centralizes process safety information, including chemical hazards, safety data sheets, and SOPs

- Enables structured risk assessments like HAZOPs, What-If, and FMEA

- Manages incident investigation processes with detailed workflows and root cause analysis

- Tracks compliance audits, inspection histories, and corrective action statuses

- Allows documentation and tracking of emergency planning, drills, and response protocols

- Supports permit-to-work systems and contractor safety integrations

- Advanced analytics for identifying trends and contributing factors across sites

Pros

- Enterprise-grade solution with high configurability and depth

- Strong integration with other Sphera modules for EHS, sustainability, and product stewardship

- Good for multinational companies with strict regulatory demands

- Provides detailed reporting and documentation for audits and inspections

Cons

- Not cost-effective for small or mid-sized companies

- Complex interface may require dedicated training for full adoption

- Longer implementation times due to system depth and configuration requirements

4. TenForce

Source: TenForce.com

TenForce provides a flexible, process-driven platform that supports operational risk and process safety across high-hazard industries like chemicals, utilities, and manufacturing.

It’s designed for companies that need to manage both structured safety workflows and dynamic risk environments.

Key Process Safety Management Features

- Centralizes process safety information, including SOPs, asset data, and chemical inventories

- Manages risk assessments such as HAZOP, LOPA, and bowtie analyses through configurable templates

- Streamlines incident investigation with linked action tracking, timelines, and RCA tools

- Tracks compliance audits, corrective actions, and regulatory inspection readiness

- Supports permit-to-work, MOC, and contractor safety processes in real time

- Offers performance dashboards to monitor compliance and incident trends

- Integrates with EHS, Emergency Response Plan (ERP), and document control systems

Pros

- Customizable platform tailored to operational safety workflows

- Good integration capabilities across systems and departments

- Real-time collaboration tools for teams across multiple sites

- Effective visualization of risk and barrier management

Cons

- Requires configuration time to align workflows with company-specific needs

- Some advanced features may involve steep licensing tiers

- Not as widely adopted in North America compared to EU-based implementations

5. Alcumus SafeContractor

Source: Cognibox.com

Formerly called Cognibox, Alcumus SafeContractor specializes in managing contractor compliance, training, and safety documentation, with strong applications for process industries.

While not a full end-to-end PSM system, it fills a critical role in ensuring contractor safety aligns with internal process safety programs.

Key Process Safety Management Features

- Centralizes contractor safety data, training records, and prequalification results

- Tracks compliance documentation tied to chemical handling, PPE, and job-specific hazards

- Supports incident reporting, investigation workflows, and safety performance tracking

- Offers audit readiness tools to ensure contractors meet internal and regulatory PSM requirements

- Enables the delivery of safety training modules and tracks completion across distributed teams

- Customizable interface for aligning with organization-specific safety policies

- Provides analytics for identifying gaps in contractor readiness and compliance

Pros

- Good contractor-focused compliance features that support PSM-adjacent workflows

- Simple user interface for both safety managers and third-party users

- Scalable across industries with multilingual support

- Well-suited for companies with high contractor turnover or multi-tiered supply chains

Cons

- Not a full PSM solution; better as a complement to other process safety platforms

- Limited native risk analysis tools compared to dedicated PSM software

- Customization may be needed to align tightly with complex industrial safety systems

Best Practices for Using Process Safety Management Software

To get real value from your process safety management software, you need to remember that it’s not just about logging data. You need to use your digital tools to improve safety, reduce risks, and support operational excellence.

Here are some things to keep in mind.

Bring Everything Into One Place

Start by centralizing your process safety data, including chemical management logs, incident records, and operating procedures.

When everything lives in one system, you gain better visibility, spot gaps faster, and keep your documentation consistent.

Track Issues in Real Time

Make sure your platform helps you stay ahead of potential risks.

Real-time alerts and reports allow your team to evaluate performance, manage PSM tasks across sites, and act before problems grow.

Use It to Stay Compliant

Good PSM software should make it easier to comply with OSHA regulations.

That means supporting documentation, training, emergency planning, and incident investigations, without extra manual effort.

Connect It to Your Broader Safety Tools

The best solutions work with your other safety systems, like training, inspections, and risk management, so you’re not duplicating work.

Integration leads to better productivity and stronger outcomes.

Make Sure Your Team Uses It Right

Even the best software won’t help if your team isn’t trained.

Use built-in dashboards to assign tasks, monitor overdue actions, and keep everyone accountable, especially when managing high-risk operations.

Automate Smart, Scalable Safety Management with EHS Momentum

Effective process safety management starts with the right mindset and the right software. If you’re looking to streamline risk control, strengthen compliance, and build a culture of accountability, EHS Momentum delivers the tools and support to get there.

MyMomentum: A Practical Tool for PSM Compliance

MyMomentum, developed by EHS Momentum, is a cloud-based safety platform built for companies that need powerful, practical tools to manage compliance. It allows you to:

- Track EHS training, inspections, and regulatory deadlines

- Manage incidents and process safety documentation

- Monitor employee performance and overdue actions

- Stay compliant with OSHA’s process safety management guidelines

- Maintain records across inspections, equipment, and chemical storage

This all-in-one platform supports small and growing teams in their efforts to stay compliant, reduce property damage, and protect employees, all without overcomplicating daily operations.

Want to see it in action? Schedule a demo with EHS Momentum.

FAQs About Process Safety Management Software

What is a process safety management program?

A PSM program is a structured approach to managing hazards associated with highly hazardous chemicals. It includes procedures, training, and emergency planning to help companies ensure regulatory compliance, reduce risks, and prevent major incidents.

What is a PSM software?

PSM software helps companies implement and manage their process safety programs by organizing data, tracking tasks, and streamlining compliance with OSHA’s process safety management standards.

What is safety management software?

It’s a digital tool that helps businesses manage risk, track safety standards, and ensure compliance with regulations. It often includes modules for inspections, training, audits, and incident reporting.

What are the 4 pillars of process safety?

The four pillars are:

- Commitment to process safety

- Understanding hazards and risks

- Managing risk

- Learning from experience

Each supports strong risk management and operational excellence through documented procedures, insights, and safety practices.